Intelligent, flexible and connected systems in products and production

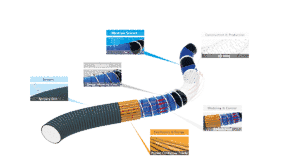

3D Printing of Multi-Functional Structures by Eric MacDonald Ph.D., P.E.

3D printing has generally been relegated to fabricating conceptual models and prototypes; however, increasingly, research is now focusing on fabricating functional end-use products. As patents for 3D printing expire, new low cost desktop systems are being adopted more widely and this trend is leading to products being fabricated locally. However, currently the techonlogy is limited in the number of materials used in fabrication and consequently is confined to fabricating simple static structures. For additively manufactured products to be economically meaningful, additional functionalities are required to be incorporated in terms of electronic, electromechanical, electromagnetic, thermodynamic, chemical and optical content. By interrupting the 3D printing and employing complementary manufacturing processes, additional functional content can be included in mass-customized structures. This presentation will review work in multi-process 3D printing for creating structures with consumer-specific wearable electronics, electromechanical actuation, electromagnetics, propulsion and embedded sensors in soft tooling and even in metal and ceramic structures.

Soft Material Robotic Systems by Prof. Dr.-Ing. Annika Raatz

Major robot manufacturers and trend scouts have been proclaiming a revolution in the role of robotics in our every lives. However, as the bars behind which industrial robots have been looming for long are being obliterated, images that may well originate in science fiction movies cross one’s mind. Only recently have robotics researchers begun to initiate a paradigm shift in the design of robotic systems, which may one day cause a change of mindset and provoke pictures of more human-friendly robots that harmlessly interact with us. With a deeper understanding of how soft-bodied animals achieve highly sophisticated and flexible behaviors through softness, such as the remarkable manual grasping ability exhibited by the octopus vulgaris, researchers are now translating their insights into the design of robotic systems that are made mainly of soft materials. This paradigm shift from stiff to soft is not limited to the need for novel approaches for the mechanical design of these robotic systems; it also presents challenges for the design of smart materials and components as well as for modeling and control.

Soft Squishy Electronic Skin by Prof. Ravinder Dahiya

The miniaturization led advances in microelectronics over 50 years have revolutionized our lives through fast computing and communication. Recent advances in the field are propelled by applications such as electronic skin in robotics, wearable systems, and healthcare technologies etc. Often these applications require electronics to be soft and Squishy so as to conform to 3D surfaces. These requirements call for new methods to realize sensors, actuators electronic devices and circuits on unconventional substrates such as plastics, papers and elastomers. This lecture will present various approaches (over different time and dimension scales) followed for obtaining distributed electronic, sensing, actuation and computing devices on soft and flexible substrates, especially in context with the tactile or electronic skin (eSkin). These approaches range from distributed off-the-shelf electronics integrated on flexible printed circuit boards, to novel alternatives such as eSkin constituents obtained by printed nanowires, graphene and ultra-thin chips, etc. The technology behind such sensitive flexible and squishy electronic systems is also the key enabler for numerous emerging fields such as internet of things, smart cities and mobile health etc. This lecture will also discuss how the flexible electronics research may unfold in the future.